Renewable Diesel

Sample Project

Homeland Fuels

BCA advised Homeland Fuels Company on the development of their Pennsylvania and Maine bio-mass to renewable diesel projects. BCA provided financial advisory services including project financing, attributes included RINs and Production Credits, and state incentive programs.

Homeland Fuels is an innovative energy company that utilizes advanced conversion technologies to process renewable cellulosic biomass feed stocks into synthetic ultra-clean transportation fuels and related products.

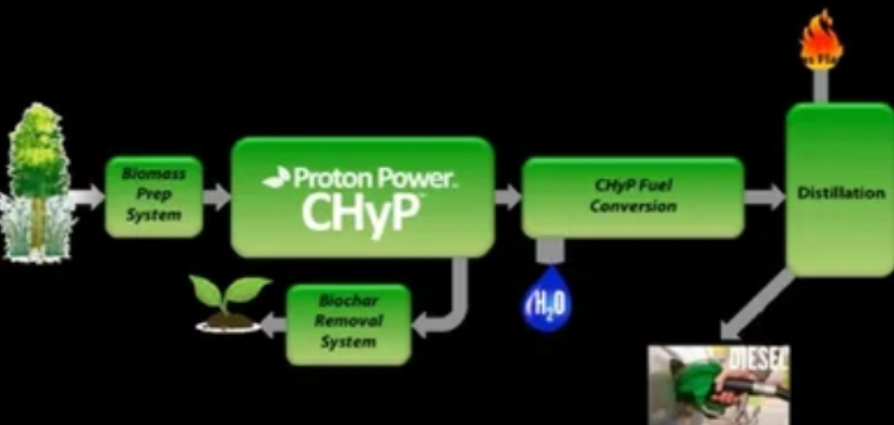

Renewable biomass feedstock is processed through a proprietary, high temperature pyrolysis technology from Proton Power Inc. (“PPI”) that converts the wood material into multiple high-value products:

– Renewable diesel fuel that exceeds ultra-low sulfur, on-road specifications. This is “drop in” diesel fuel and qualifies for the Federal renewable fuel credits and California Low Carbon Fuel Credits

– Biochar that is an outstanding and valuable organic fertilizer; and

– Bulk Graphene which is derived from the Biochar in a secondary process.

The Process utilized Proton Power’s Cellulose-to-Hydrogen Power (CHyP®) pyrolysis unit to convert biomass into renewable diesel and other valuable co-products. The carbon in the biomass feedstock is sequestered in the biochar or graphene. The entire process has a very low carbon intensity and produces a high-quality diesel fuel that is well suited to markets like California that offer incentives based on the low carbon intensity of the fuel. The biochar can be used directly out of the production plants as an excellent soil amendment, or it can be converted to a much higher value product: graphene. (www.homelandfuelscompany.com)

Sample Project

Home Grown Fuels

BCA initially worked with Home Grown Fuels to apply for the Integrated Biofuels Production Enterprise (IBPE) for a US$55 million grant. The team established was BCA, Home Grown Fuels. University of Maine, Proton Power, and Permitting Partners to apply for the Government grant program to establish or expand commercial-scale manufacture and supply of drop-in replacement biofuels for aviation and marine diesel applications. The program was for the design, construction and/or retrofit, operation, validation and qualification of a domestic commercial-scale IBPE that meets a requirement of at least 10 million gallons per year neat biofuel production capacity. The targeted fuels will be for military operational use, and as such, must be approved and certified MILSPEC JP-5, MILSPEC JP-8, approved for US military use ASTM D1655 / D7566 Jet A/A1 and/or MILSPEC F-76 equivalents by the time a commercial-scale IBPE would become operational.

Subsequent to the grant application work BCA continued to work with Home Grown Fuels providing financial, strategic, and business development services for the development of their beta plant to be located in Maine. The company was planning to convert renewable biomass feedstock processed through a proprietary, high temperature pyrolysis technology from Proton Power Inc. (“PPI”) that converts the wood material into renewable diesel fuel that exceeds ultra-low sulfur, on-road specifications. This is “drop in” diesel fuel and qualifies for the Federal renewable fuel credits and California Low Carbon Fuel Credits

HGF changed course and is pursuing converting biochar into bulk graphene through a secondary process. www.homegrownfuels.com